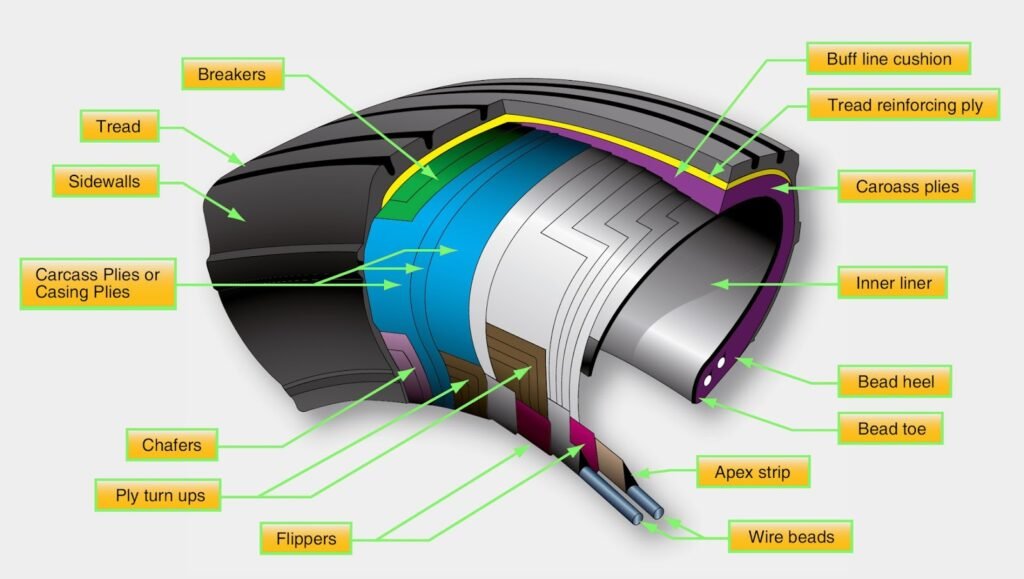

| Component | Location | Function / How it helps resist wear / stress |

| Tread | Outermost surface contacting runway | Made of a hard, wear-resistant rubber compound. Designed to resist abrasion, chunking, and heat. May have shallow grooves for water evacuation but generally minimal pattern to maximize contact and durability. |

| Cap or overlay layer | Immediately beneath tread | Sometimes a tougher “cap” layer is used under the tread to take most of the wear, protecting underlying layers. |

| Belt or reinforcing plies | Just under the tread / overlay | Fibers (nylon, aramid, etc.) provide hoop strength, help control deformation, spread stresses, and reduce heat build-up. |

| Carcass plies | Mid-section wrapping around the tire | Provide bulk of structural strength. These plies hold the tire shape under pressure and load, reducing internal flexing and fatigue. |

| Sidewalls | Flanks of the tire between tread and bead | The rubber and reinforcement here must balance flexibility with strength, resisting cracking or tearing under lateral / bending stresses. |

| Inner liner / air-holding layer | On the inside surface | Seals the pressurized gas (often nitrogen) inside the tire. Prevents leakage and helps maintain stable pressure so that outer layers don’t overheat due to under-inflation. |

| Bead / bead bundle | The edge that mates to the wheel rim | Reinforced to maintain a strong, consistent seal and to resist shear stresses when mounting, braking, or accelerating. |

| Apex / filler / shoulder reinforcement | Between carcass and sidewall / near edges | Gradually transitions stiffness between sidewall and tread, smoothing stress gradients and reducing localized wear. |

| Flippers / chafer protection | At edges adjacent to bead | Protects from abrasion, chafing, or damage from the wheel or mounting equipment. |