In the Goodyear Aviation Tire Data Book, “higher percent deflection” has a very specific engineering meaning tied directly to how much an aircraft tire is designed to deform under load, and why that deformation is intentionally allowed.

What “Percent Deflection” Means in Aircraft Tires

Percent deflection is the ratio of how much the tire deflects (flattens) under rated load to its unloaded section height, expressed as a percentage.

In simple terms:

Percent deflection = how much the tire “squats” under load

Example (conceptual)

- Unloaded tire section height: 10.0 inches

- Loaded deflection at rated load: 2.0 inches

- Percent deflection = 20%

Aircraft tires typically operate at much higher deflection levels than automotive tires.

What “Higher Percent Deflection” Refers To

When Goodyear designates a tire size with a leading letter (such as “H”), it indicates a tire engineered to safely operate at a higher allowable deflection percentage than a standard tire of similar size.

This means:

- The tire is intentionally more flexible

- The carcass, ply angles, cord materials, and bead design are optimized to tolerate greater flattening without structural damage

This is not under-inflation.

It is by design and fully within certification limits.

Why Higher Percent Deflection Matters

1. Energy Absorption During Landing

Aircraft tires are a primary shock-absorbing component of the landing gear system.

Higher percent deflection allows the tire to:

- Absorb more vertical impact energy

- Reduce peak loads transmitted to:

- Landing gear struts

- Wheels

- Axles

- Airframe attach points

This is particularly important for:

- High sink-rate landings

- Short-field operations

- Aircraft with limited strut travel

2. Load Distribution and Footprint Size

A higher-deflection tire produces:

- A larger, more compliant contact patch

- Better load distribution across the tread

Benefits:

- Reduced runway surface stress

- Improved braking traction

- Lower likelihood of localized tread wear

3. Compatibility With Specific Landing Gear Designs

Some aircraft landing gear systems are designed assuming:

- Greater tire compliance

- Less reliance on oleo strut stroke

In these cases, a standard-deflection tire may:

- Transfer excessive loads into the gear

- Cause harsh landings

- Accelerate structural fatigue

The “H” designation ensures the tire matches the landing gear’s mechanical assumptions.

4. Structural Design Implications

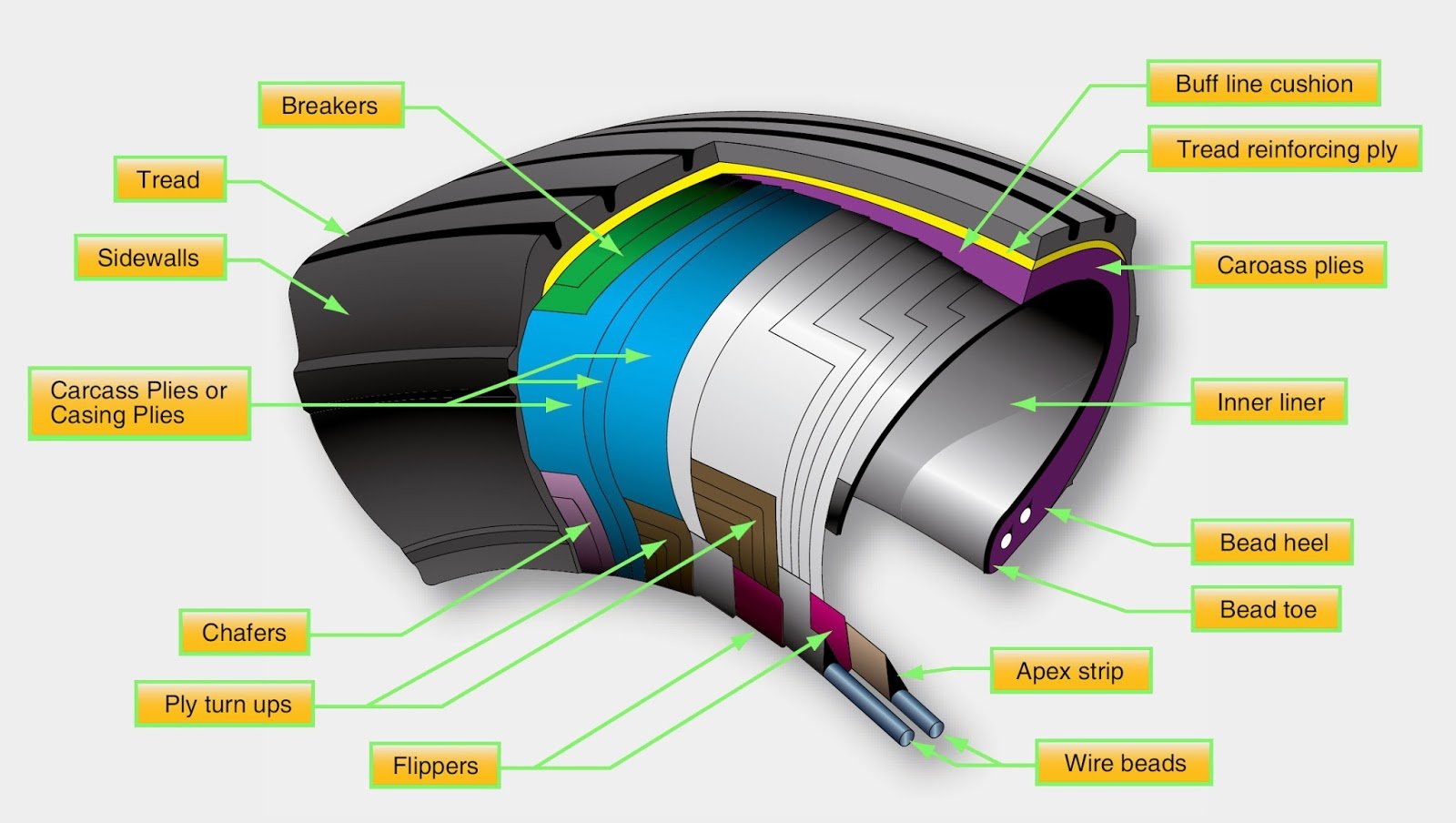

To tolerate higher deflection safely, these tires typically incorporate:

- Reinforced bias-ply carcass geometry

- Optimized cord angles to manage shear

- Bead and chafer designs that resist rim slip

- Sidewall compounds formulated for repeated flexing

This is why not all tires of the same nominal size are interchangeable, even if load ratings appear similar.

Why Goodyear Explicitly Calls This Out

Goodyear highlights higher percent deflection because:

- Incorrect substitution of a lower-deflection tire can:

- Reduce landing gear life

- Increase wheel and brake stress

- Raise the risk of ply separation or bead damage

- Maintenance and procurement teams must ensure:

- The exact size classification is installed

- Inflation pressures are set per the specific tire design, not just size

This is especially critical in:

- Business jets

- High-cycle corporate aircraft

- Aircraft operating near max gross weight

Practical Summary

Higher percent deflection means the tire is:

- Designed to flex more under load

- Certified to safely absorb higher landing energies

- Matched to aircraft that rely on tire compliance as part of their landing-gear system

It matters because it directly affects:

- Landing impact loads

- Gear and airframe fatigue life

- Braking performance

- Tire durability and safety margins

Leave a Reply