What is an Aircraft Tire “Casing”?

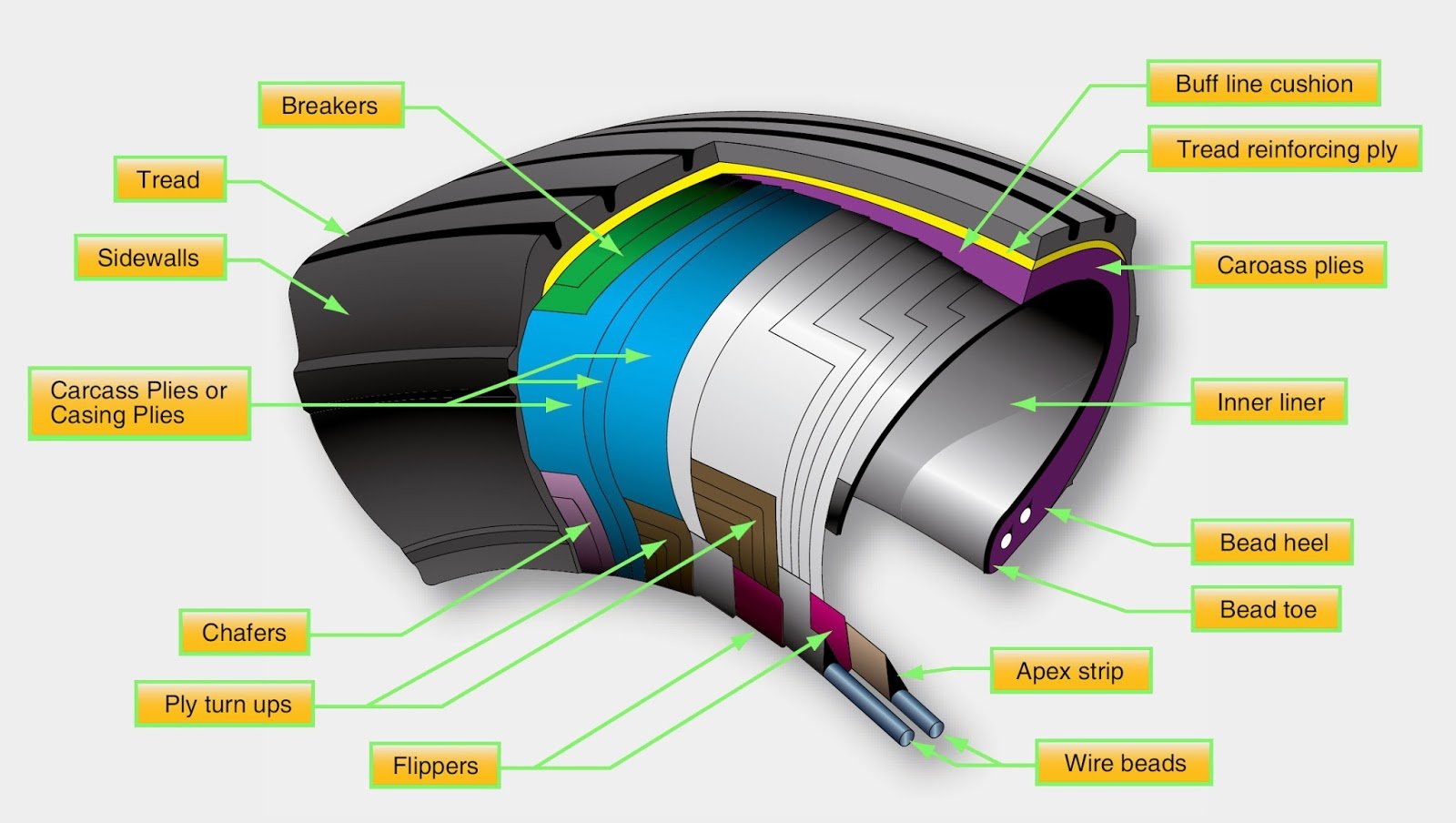

- The casing is the structural body of the tire — all the layers of fabric, cords, plies, beads, and inner liner that form the tire’s skeleton.

- The tread rubber is applied over the casing, but it’s the casing that actually carries the aircraft’s weight and resists the massive forces of takeoff/landing.

- In fact, in aviation tire maintenance, a casing that passes inspection can be retreaded many times, while the tread rubber is replaced.

Think of it as the chassis of the tire — the reusable backbone.

What is the Casing Made Of?

- Cord plies: Nylon, polyester, aramid (Kevlar®), or hybrid composites laid at angles to provide strength.

- Carcass plies: Layers of cords embedded in rubber that give the tire its main load-carrying capacity.

- Belts / breakers (in radials): Additional circumferential layers that stabilize the tread and casing.

- Beads: Bundles of steel wire that anchor the casing to the wheel rim.

- Inner liner: Airtight rubber compound that seals in nitrogen or air.

How is Casing Strength “Calculated” or Rated?

The casing’s capacity is not expressed as a single number, but evaluated through design + certification tests:

- Ply Rating / Load Rating

- The casing’s plies determine how much weight the tire can carry.

- Example: A 26-ply rating casing can withstand far higher loads than a 12-ply rating casing, even if both are the same size.

- The casing’s plies determine how much weight the tire can carry.

- Bead Strength

- The casing must lock to the rim without slipping or distorting under high torque and braking loads.

- The casing must lock to the rim without slipping or distorting under high torque and braking loads.

- Burst Strength Tests

- The casing is pressurized until failure to verify a large safety margin (often 4x rated pressure).

- The casing is pressurized until failure to verify a large safety margin (often 4x rated pressure).

- Retreadability

- The casing is evaluated for how many times it can be safely retreaded — some Michelin/Goodyear casings last 5–7 retreads before retirement.

- The casing is evaluated for how many times it can be safely retreaded — some Michelin/Goodyear casings last 5–7 retreads before retirement.

How Does the Casing “Work”?

- Load Distribution:

The cord plies in the casing spread the aircraft’s weight across the footprint so no one spot takes all the stress. - Shape Control:

The casing resists deformation (ballooning) under high pressure (~200 psi) and high centrifugal force at landing speeds (200+ mph). - Heat Management:

The casing structure allows heat to dissipate from tread and sidewalls, preventing reversion and delamination. - Flex & Shock Absorption:

The casing flexes just enough to absorb impact on landing, but not so much that it overheats or distorts.

Why the Casing is Critical

- The casing is the most expensive part of the tire. The tread is consumable, but the casing is designed to last for years.

- If the casing is damaged (cuts, exposed cords, ply separations, sidewall bulges), the tire must be scrapped — no retread allowed.

- Operators track casings by serial number to maximize lifecycle cost: retread after retread until casing fatigue retires it.

Summary

- Casing = structural body of the tire.

- Built of plies, beads, liner, and reinforcement layers.

- Its strength is tested by ply rating, burst tests, and retreadability.

- It works by distributing load, resisting distortion, and handling heat.

- Retreading makes the casing the most valuable part of an aircraft tire.